A pure metal has one specific melting point.

4047 aluminium sheet.

At rickard specialty metals we have 30 years of experience supplying 4047 aluminum sheet forgings and more to your custom measurements.

4047 is the aluminum association aa designation for this material.

For all stock availability for aluminium alloy 4047 contact sales.

4047 aluminum is a 4000 series aluminum alloy.

Cited properties are appropriate for the as fabricated no temper or treatment condition.

4047 aluminum flat stock list 4047 aluminum round stock list 4047 aluminum combo stock list.

Aluminum 4047 is one of the most popular types of aluminum alloy.

4047 aluminum sizes available for 1 day shipment the below sizes are in stock.

4047 a is also available in brazing filler metal welding rod and electrodes.

1 requires sufficient dilution of base metal into weld pool for heat treat and or age response.

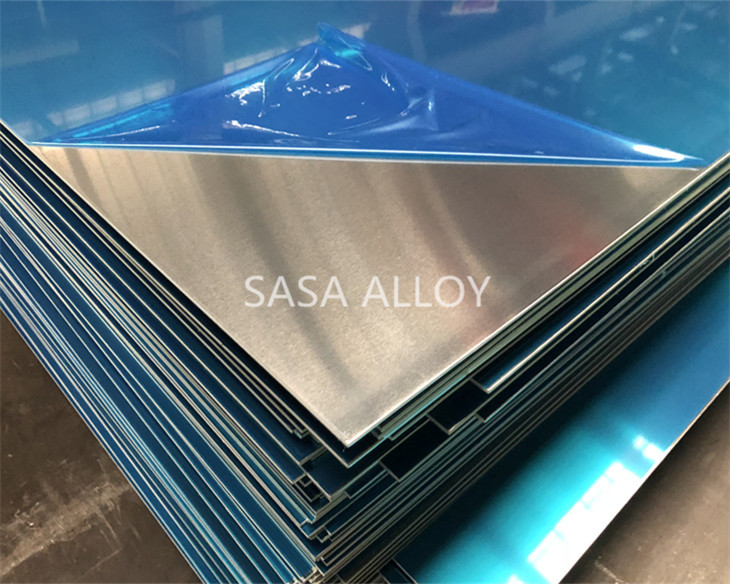

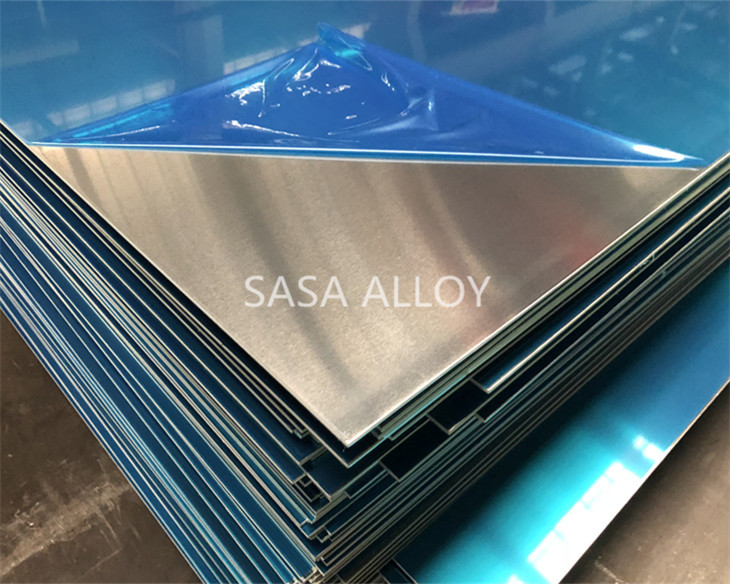

4047 aluminum sheets al plate product introduction.

Aluminum 4047 s higher silicon content minimizes its shrinkage and gives it a smooth finish setting it apart from aluminum 4043.

The main difference between 4043 and 4047 is the silicon content of these alloys.

In european standards it will be given as en aw 4047.

Our forging process includes open die forgings ring rolling and more.

Often compared with aluminum 4043 it s a non heat treated alloy primarily composed of silicon iron copper zinc magnesium and aluminum.

The main alloying addition is silicon.

See below for a list of common forged shapes we offer including 4047 aluminum bar round bar and flat bar and more.

Balsi 4 is the aws designation.

However an alloy melts over a range of temperatures.

The main difference between alloy 4047 and it s al4043 counterpart is its higher silicon content.

Custom sizes can be produced quickly.

The additional silicon has several effects.

Regarding differences between 4043 and 4047 4043 basically is aluminum with 5 percent silicon added while 4047 is aluminum with 12 percent silicon added.

The 4043 filler alloys contain 4 5 to 6 0 silicon and the 4047 contain 11 0 to 13 0.

Alloys 4043 and 4047 are considered the same for properties per aws d1 2 structural welding code.

Refer to alcotechnic concerning alloy 4643 for additional information.

Uns a94047 bs n2 awco 40 star si 120 fed qq b 655 class fs ba1 si 3 ams 4185 filler metal.

The filler alloy 4047 was originally developed as a brazing alloy balsi 4 or 718 taking advantage of its low melting point and narrow freezing range 1070 to 1080 deg f.

2 postweld aged only.