We carry aluminum sheet plate in 1100 h14 1100 h112 2024 t3 t351 2024 o clad 2024 t3 clad 3003 h14 5005 anodized black 5005 anodized dark bronze 5005 anodized clear 5052 h32 5052 h32 dfars 5086 h32 6061 o 6061 t4 6061 t6 t651 6061 dfars domestic 7050 t7451 7075 t6 t651 7075 t6 clad 7075 o 7075 o clad.

3003 clad aluminum sheet.

It is one of the most commonly used of all aluminium alloys essentially commercially pure aluminium with.

Mill finish not polished.

Its use should result in greatly increased life of a structural part.

Choose from our selection of aluminum sheet metal in a wide range of styles and sizes.

3003 h14 aluminum sheet astm b209 qq a 250 2 excellent weldability and formability with good corrosion resistance makes 3003 aluminum sheet a popular and economical choice.

3003 aluminum stands up to outdoor use as well as exposure to chemicals.

Not all aircraft sheet aluminum is clad especially those alloy sheets from which small brackets gussets and fittings are made.

Fuel tanks food chemical handling trailer siding roofing etc.

It offers a good combination of strength formability and weldability.

The pure aluminum is very soft and fabrication processes would severely damage or destroy the clad surfaces.

It melts and flows during the brazing process to provide upon cooling a metallic bond between the components.

The material was described in naca tn 259 of august 1927 as a new corrosion resistant aluminum product which is markedly superior to the present strong alloys.

In stock and ready to ship.

3003 aluminum sheet has a smooth semi shiny finish and is popular for many applications including.

It s often used for storage tanks heat exchangers garage doors and general sheet metal work.

Alclad is a heat treated aluminum copper manganese magnesium alloy that has the corrosion resistance of pure metal at the surface and the strength of.

An example of clad aluminum is the surface of unpainted aircraft.

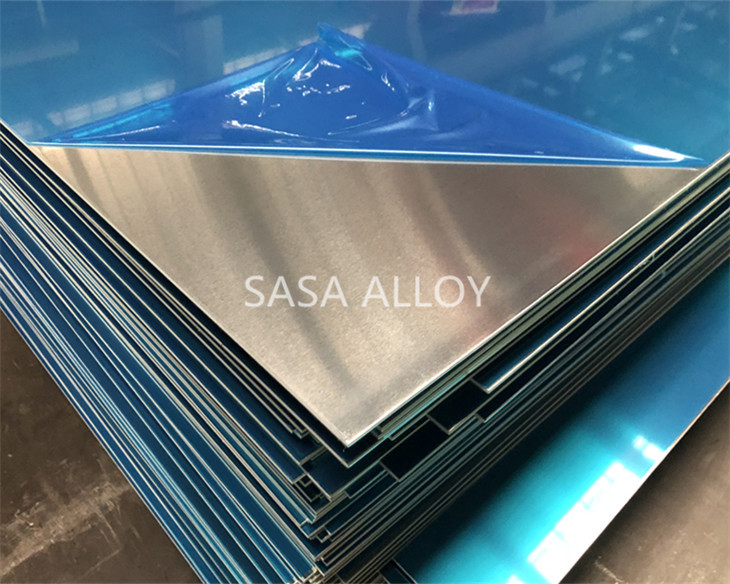

Aluminum sheet metal comes in a variety of thicknesses and weights in many different grades.

Brazing sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum silicon al si alloy.

This thin layer usually makes up 5 to 10 of the total thickness of the brazing sheet.

These sheets are clad in 1230 aluminum for an added layer of corrosion resistance.

3003 this is the most widely used of all aluminum alloys.